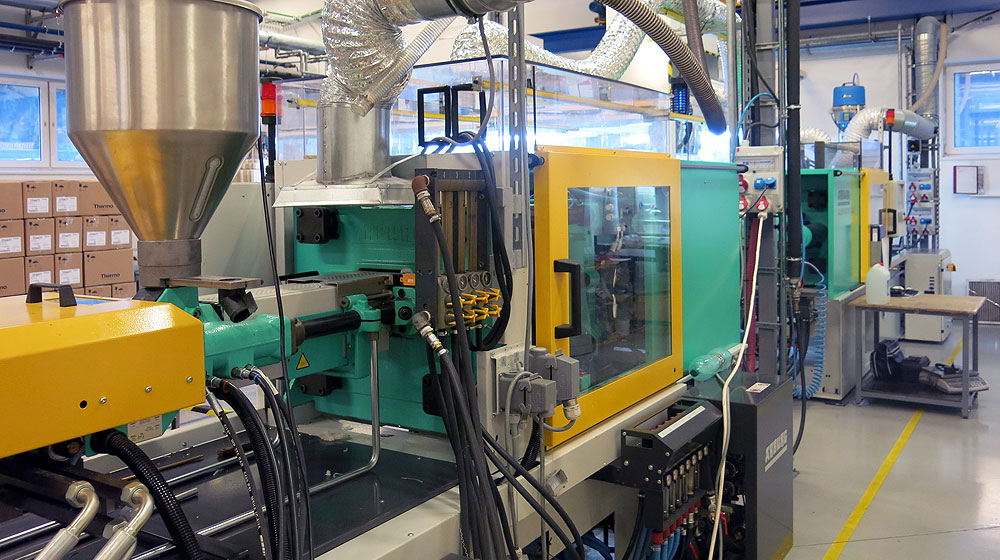

Injection Moulding

Thermoset Injection Moulding

Thermoset Injection moulding is also known as DST, (direct screw transfer) moulding.

At Coleshill Plastics we have a dedicated range of thermoset injection machines that give us the capability to produce products /components with shot weights of a few grams up to over 3.4 kilos, in materials which include: Melamine, Urea, Phenolic (Bakelite), BMC (Bulk Moulding Compound). These materials come in various forms including: Granulated Powder, Pellets and Fibrous Dough which requires specialised feeding equipment on the injection unit.

The material is fed, plasticised and metered in the machines barrel and screw and then injected under high pressure into a closed heated mould and held under pressure until cured.

In addition the machines are equipped with vacuum extraction to enable fast injection speeds required to achieve cosmetic surface finishes, without the associated gas trapping.

Thermoplastic injection Moulding

We have thermoplastic injection machines fitted with multi-zone heating and cooling to accommodate the high specification engineering thermoplastics increasingly being specified by our customers which include Peek, Ultem, Polycarbonate, and a host of more general materials such as Nylons, Acetal, ABS, Polypropylene.

The thermoplastic injection moulding process uses pellets of material that are fed, plasticised and metered in the machines heated barrel and screw. The molten polymer is then injected into a closed metal mould at high pressure and held under pressure until cooled sufficiently to allow ejection

Thermoplastic injection moulding is used in the manufacture of an extremely wide range of products from everyday packaging and bottle caps to high specification aerospace components.

If you would like more information about any of the products and services we offer please contact us or call us directly on 02476 724 900.

Get in touch With Us

Want to work with us? Please feel free to contact us for any inquiry you may have.